- No.3, 327 S.V.P.Road, Makharai House, Mumbai- 400004, INDIA

- sales@ariesalloys.com

Global Titanium Trends: Strength, Innovation & Demand

- Home

- Titanium Alloy Market Analysis

Titanium Alloy Market Analysis: Global Trends, Growth Forecasts, and Industry Opportunities (2023-2029)

Introduction to the Global Titanium Alloy Market

The titanium alloy market is expanding rapidly due to its high strength-to-weight ratio, corrosion resistance, and biocompatibility. Titanium alloys are essential in industries such as aerospace, medical, automotive, marine, and energy due to their superior mechanical properties.

Market Size & Growth Rate (2023-2029)

The global titanium alloy market was valued at $6.5 billion in 2023 and is projected to reach $10.2 billion by 2029, growing at a CAGR of 7.8%. Key factors driving this growth include:

✅ Increasing demand for lightweight materials in aerospace & defense

✅ Growing use of titanium in medical implants & prosthetics

✅ Expanding applications in the automotive and EV sector

✅ Advancements in titanium-based 3D printing & additive manufacturing

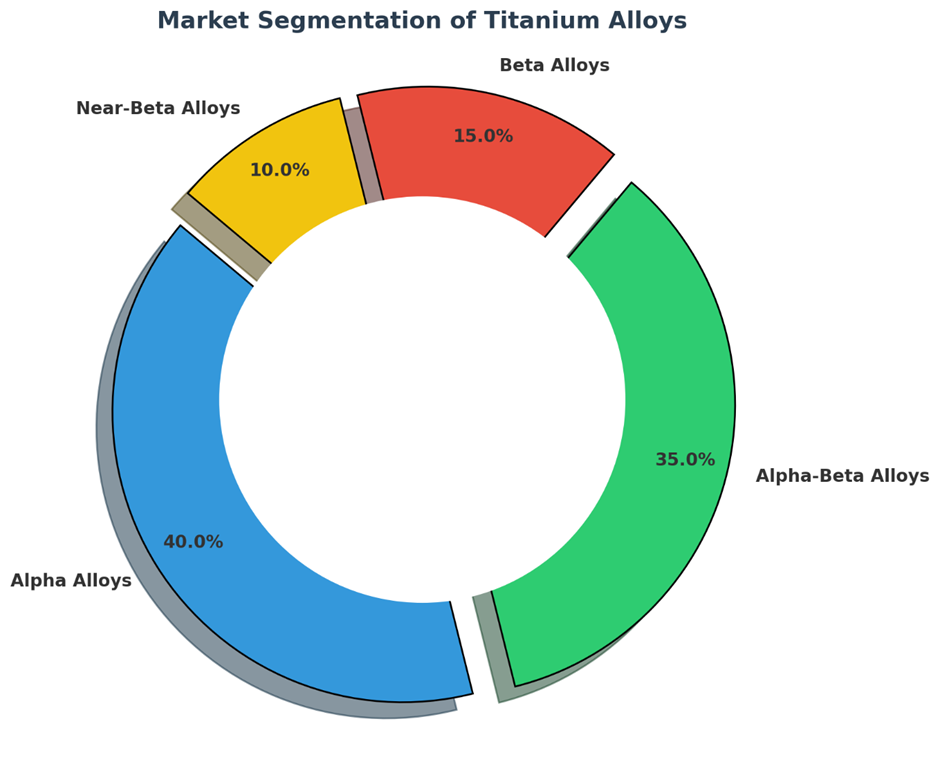

Market Segmentation: Types of Titanium Alloys

1. Alpha Alloys (40% Market Share) – High-Temperature Resistance

🔹 Used in: Jet engines, aircraft frames, and nuclear reactors.

🔹 Examples: Ti-6Al-2Sn-4Zr-2Mo

🔹 Key Features: Oxidation resistance, good weldability

2. Alpha-Beta Alloys (35% Market Share) – Most Commonly Used

🔹 Used in: Aerospace structures, medical implants, and chemical processing.

🔹 Examples: Ti-6Al-4V (Most widely used titanium alloy)

🔹 Key Features: Balanced strength, flexibility, and corrosion resistance

3. Beta Alloys (15% Market Share) – High Strength & Ductility

🔹 Used in: Automotive, sports equipment, and deep-sea applications.

🔹 Examples: Ti-10V-2Fe-3Al

🔹 Key Features: Excellent toughness, heat treatable

4. Near-Beta Alloys (10% Market Share) – High-Performance Engineering

🔹 Examples: Ti-5Al-5Mo-5V-3Cr

🔹 Key Features: High strength-to-weight ratio, enhanced fatigue resistance

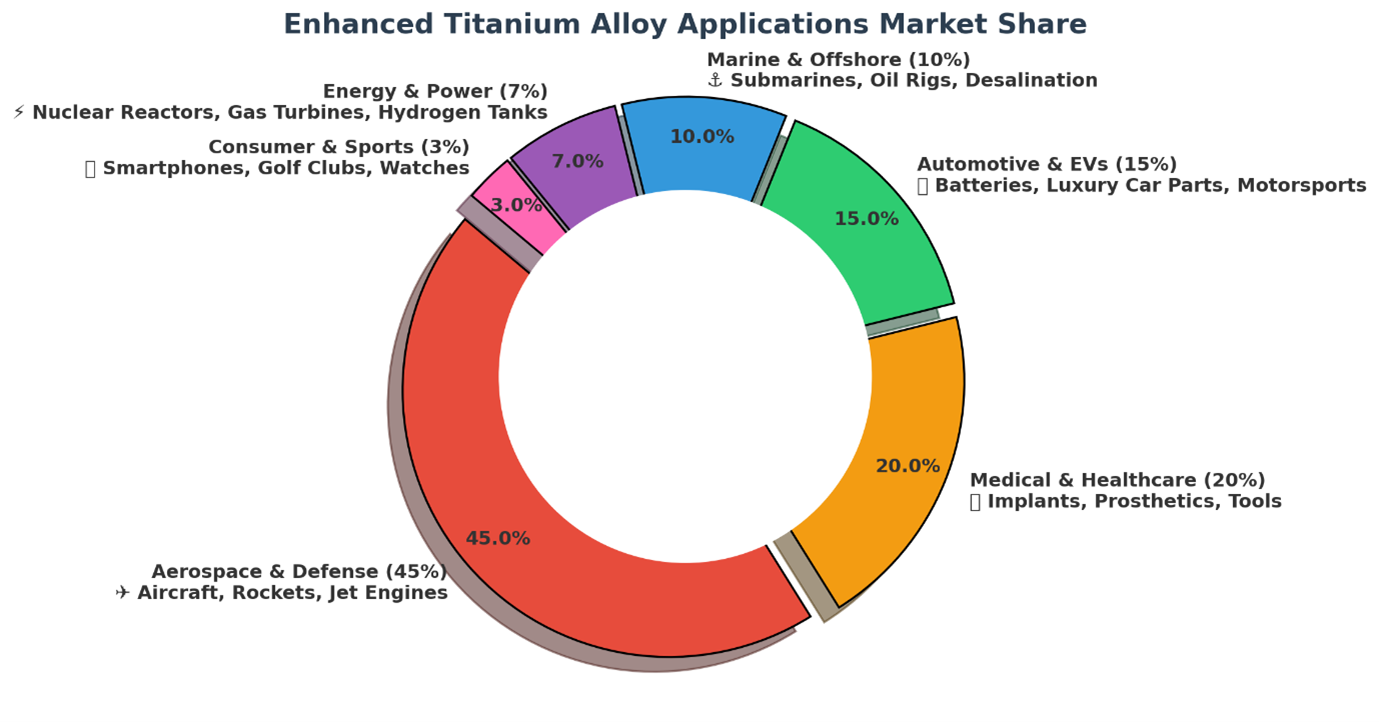

Key Industry Applications of Titanium Alloys

1. Aerospace & Defense Industry (45% Market Share) ✈️

- Aircraft Frames & Engine Components – Reducing weight for fuel efficiency.

- Rocket & Missile Components – High strength-to-weight ratio in space programs.

- Jet Engine Turbines & Exhaust Systems – Heat and corrosion resistance.

🌍 Top Regions: USA, Europe, China, Russia

2. Medical & Healthcare Industry (20% Market Share) 🏥

- Titanium Implants & Prosthetics – Biocompatible & long-lasting.

- Orthopedic & Dental Implants – Used in artificial joints, plates, and screws.

- Medical Tools & Devices – Hypoallergenic and durable.

🌍 Top Regions: USA, Germany, Japan, India

3. Automotive & Electric Vehicles (EVs) (15% Market Share) 🚗

- Titanium-Based EV Batteries – Lightweight and heat-resistant.

- Performance & Luxury Car Components – Titanium exhaust systems & engine parts.

- Structural Components in Motorsports – Reducing vehicle weight for speed.

🌍 Top Regions: Germany, USA, Japan, China

4. Marine & Offshore Industry (10% Market Share) 🚢

- Naval Submarines & Deep-Sea Vessels – Extreme corrosion resistance.

- Oil & Gas Rigs – Titanium pipelines for longevity.

- Desalination Plants – Titanium heat exchangers in water treatment.

🌍 Top Regions: Norway, USA, South Korea, Middle East

5. Energy & Power Industry (7% Market Share) ⚡

- Nuclear Reactor Components – Radiation-resistant titanium alloys.

- Gas & Steam Turbines – Heat resistance in energy plants.

- Hydrogen Storage Tanks – Essential for renewable energy transition.

🌍 Top Regions: USA, China, France, Canada

6. Consumer Electronics & Sports Equipment (3% Market Share) 🎧

- Smartphones & Wearable Devices – Lightweight & durable casing.

- Golf Clubs, Bicycles, & Tennis Rackets – High strength and flexibility.

- Luxury Watches & Jewelry – Corrosion-resistant and hypoallergenic.

🌍 Top Regions: USA, Switzerland, South Korea, Japan

Market Challenges & Risks

🚧 High Production Costs – Complex refining process increases costs.

🚧 Limited Raw Material Availability – Dependence on titanium ore mining.

🚧 Processing & Machining Difficulties – Requires specialized manufacturing.

🚧 Recycling & Environmental Impact – New eco-friendly processes needed.

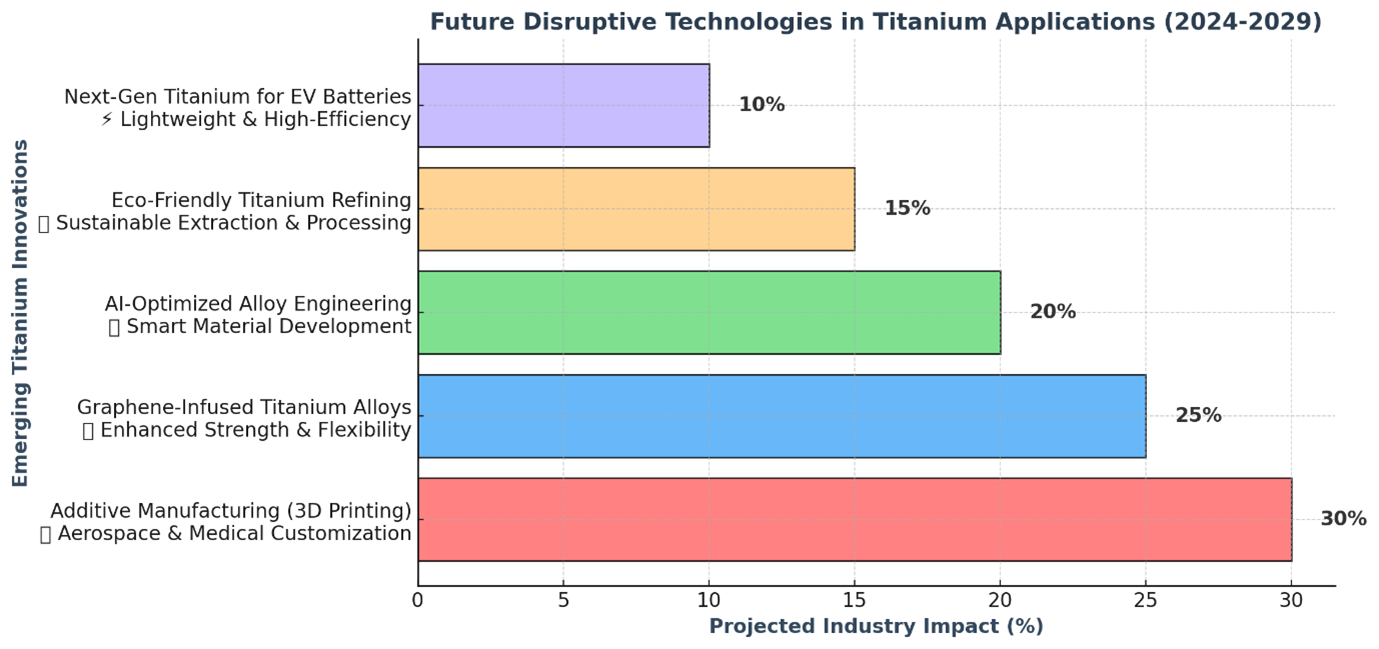

Future Trends & Innovations (2024-2029)

🔹 Titanium-Based 3D Printing (Additive Manufacturing) – Custom aerospace & medical components.

🔹 Titanium Graphene Composites – Stronger, more flexible materials.

🔹 AI-Driven Alloy Optimization – Enhancing material properties for specialized applications.

🔹 Sustainable Titanium Extraction – Eco-friendly refining processes.

🔹 Ultra-Light Titanium for EV Batteries – Boosting energy efficiency.