- No.3, 327 S.V.P.Road, Makharai House, Mumbai- 400004, INDIA

- sales@ariesalloys.com

Flanges

- Home

- Flanges

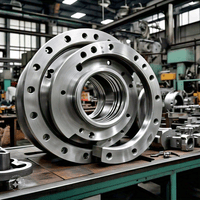

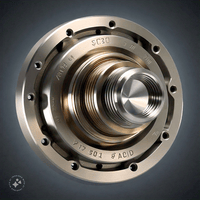

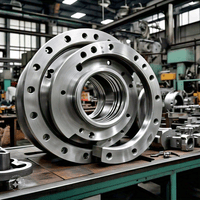

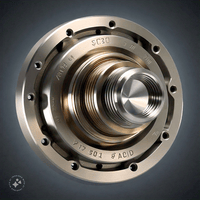

Titanium Flanges: High-Performance Piping Solutions

Titanium flanges are essential components in piping systems, providing excellent strength, corrosion resistance, and lightweight properties. Used in industries such as aerospace, marine, chemical processing, oil & gas, and power generation, these flanges ensure secure and durable connections in high-pressure and extreme environments. Their ability to withstand harsh conditions makes them an ideal choice for industries requiring longevity and reliability in their piping systems. Titanium flanges are manufactured to meet international standards such as ASTM, ASME, ANSI, DIN, and JIS, ensuring compatibility with a wide range of industrial applications. They are available in both seamless and welded forms, making them highly versatile in different piping setups.

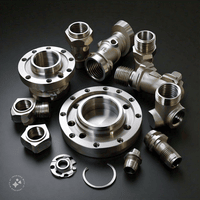

Types of Titanium Flanges & Standard Sizes

Titanium flanges are available in various types to meet different industrial requirements. Below are the most common types along with their standard sizes and applications:

1. Slip-On Flange

- Designed for easy installation and welding.

- Commonly used in low-pressure applications where quick assembly is required.

- Standard Sizes: 1/2" to 24"

- Industries: Chemical processing, water treatment, and general engineering.

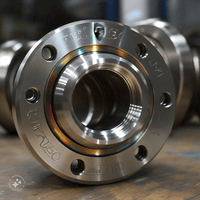

2. Weld Neck Flange

- Designed for high-pressure applications, providing strong structural integrity.

- Reduces stress concentrations and enhances durability under high pressure and temperature.

- Standard Sizes: 1/2" to 24"

- Industries: Oil & gas, aerospace, and high-temperature piping systems.

3. Blind Flange

- Used to close the end of a pipe, allowing for future modifications or maintenance.

- Ideal for high-pressure and high-temperature systems.

- Standard Sizes: 1/2" to 24"

- Industries: Power generation, petrochemicals, and pipeline systems.

4. Socket Weld Flange

- Suitable for small-diameter, high-pressure piping systems.

- Ensures a strong, leak-proof connection.

- Standard Sizes: 1/2" to 4"

- Industries: Nuclear power plants, chemical industries, and hydraulics.

5. Threaded Flange

- Used in applications where welding is not feasible.

- Commonly used in low-pressure piping and hazardous environments.

- Standard Sizes: 1/2" to 4"

- Industries: Plumbing, fire protection, and industrial gas systems.

6. Lap Joint Flange

- Used with stub ends, providing flexibility and easy bolt alignment.

- Ideal for applications requiring frequent disassembly and reassembly.

- Standard Sizes: 1/2" to 24"

- Industries: Food processing, pharmaceutical, and chemical industries.

7. Orifice Flange

- Used in flow measurement applications, often combined with orifice plates.

- Helps regulate and monitor flow rates in a pipeline.

- Standard Sizes: 1/2" to 24"

- Industries: Oil refineries, chemical processing, and water management.

8. Long Weld Neck Flange

- Designed for high-stress environments with an extended neck for reinforcement.

- Used in extreme temperature and pressure conditions.

- Standard Sizes: 1/2" to 24"

- Industries: Aerospace, power plants, and cryogenic systems.

9. Spectacle Blind Flange

- Used to isolate sections of a pipeline for maintenance or safety purposes.

- Designed as a single unit with an open and closed section for easy operation.

- Standard Sizes: 1/2" to 24"

- Industries: Refineries, offshore drilling, and gas transportation.

10. Reducing Flange

- Used to connect pipes of different diameters in a pipeline system.

- Helps regulate flow and transition between varying pipe sizes.

- Standard Sizes: Custom sizes available upon request.

- Industries: HVAC systems, chemical processing, and water distribution.

Titanium flanges are available in various types to meet different industrial requirements. Below are the most common types along with their standard sizes and applications:

1. Slip-On Flange

- Designed for easy installation and welding.

- Commonly used in low-pressure applications where quick assembly is required.

- Standard Sizes: 1/2" to 24"

- Industries: Chemical processing, water treatment, and general engineering.

2. Weld Neck Flange

- Designed for high-pressure applications, providing strong structural integrity.

- Reduces stress concentrations and enhances durability under high pressure and temperature.

- Standard Sizes: 1/2" to 24"

- Industries: Oil & gas, aerospace, and high-temperature piping systems.

3. Blind Flange

- Used to close the end of a pipe, allowing for future modifications or maintenance.

- Ideal for high-pressure and high-temperature systems.

- Standard Sizes: 1/2" to 24"

- Industries: Power generation, petrochemicals, and pipeline systems.

4. Socket Weld Flange

- Suitable for small-diameter, high-pressure piping systems.

- Ensures a strong, leak-proof connection.

- Standard Sizes: 1/2" to 4"

- Industries: Nuclear power plants, chemical industries, and hydraulics.

5. Threaded Flange

- Used in applications where welding is not feasible.

- Commonly used in low-pressure piping and hazardous environments.

- Standard Sizes: 1/2" to 4"

- Industries: Plumbing, fire protection, and industrial gas systems.

6. Lap Joint Flange

- Used with stub ends, providing flexibility and easy bolt alignment.

- Ideal for applications requiring frequent disassembly and reassembly.

- Standard Sizes: 1/2" to 24"

- Industries: Food processing, pharmaceutical, and chemical industries.

7. Orifice Flange

- Used in flow measurement applications, often combined with orifice plates.

- Helps regulate and monitor flow rates in a pipeline.

- Standard Sizes: 1/2" to 24"

- Industries: Oil refineries, chemical processing, and water management.

8. Long Weld Neck Flange

- Designed for high-stress environments with an extended neck for reinforcement.

- Used in extreme temperature and pressure conditions.

- Standard Sizes: 1/2" to 24"

- Industries: Aerospace, power plants, and cryogenic systems.

9. Spectacle Blind Flange

- Used to isolate sections of a pipeline for maintenance or safety purposes.

- Designed as a single unit with an open and closed section for easy operation.

- Standard Sizes: 1/2" to 24"

- Industries: Refineries, offshore drilling, and gas transportation.

10. Reducing Flange

- Used to connect pipes of different diameters in a pipeline system.

- Helps regulate flow and transition between varying pipe sizes.

- Standard Sizes: Custom sizes available upon request.

- Industries: HVAC systems, chemical processing, and water distribution.

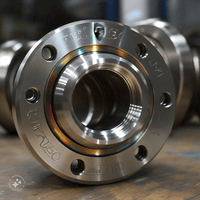

Key Advantages of Titanium Flanges

- Superior Corrosion Resistance – Titanium flanges are highly resistant to corrosion from seawater, acids, and industrial chemicals, making them ideal for harsh environments.

- Lightweight & High Strength – Titanium is about 45% lighter than steel but offers excellent strength, improving overall system efficiency.

- High-Temperature Resistance – Titanium flanges can withstand extreme temperatures, making them suitable for aerospace, nuclear, and chemical applications.

- Longevity & Durability – Titanium's resistance to oxidation and corrosion ensures a long service life, reducing maintenance costs.

- Non-Magnetic & Biocompatible – Titanium is non-toxic and non-magnetic, making it an excellent choice for medical, pharmaceutical, and food-grade applications.

- Custom Manufacturing – Titanium flanges are available in standard and custom sizes to meet the unique needs of different industries.

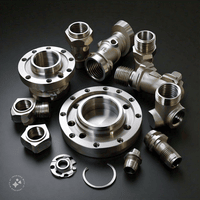

Why Choose Titanium Fasteners & Stub Ends?

- Superior Corrosion Resistance – Performs exceptionally in harsh environments like seawater and chemical exposure.

- High Strength-to-Weight Ratio – Provides excellent strength while remaining lightweight.

- Heat & Pressure Resistance – Suitable for aerospace, marine, and industrial applications.

- Custom Manufacturing – Available in standard and custom sizes based on project requirements.

Conclusion

Titanium screws, stub ends, and hex nuts provide unmatched performance for industries requiring corrosion-resistant and high-strength solutions. With a wide range of standard sizes available and custom sizes upon request, we ensure you get the perfect fit for your applications.

For further inquiries or custom requirements, please contact us today!

Titanium screws, stub ends, and hex nuts provide unmatched performance for industries requiring corrosion-resistant and high-strength solutions. With a wide range of standard sizes available and custom sizes upon request, we ensure you get the perfect fit for your applications.

For further inquiries or custom requirements, please contact us today!