- No.3, 327 S.V.P.Road, Makharai House, Mumbai- 400004, INDIA

- sales@ariesalloys.com

Nickel Outlook: Critical Supply Chain & Future Prospects

- Home

- Nickel Alloy Market Analysis

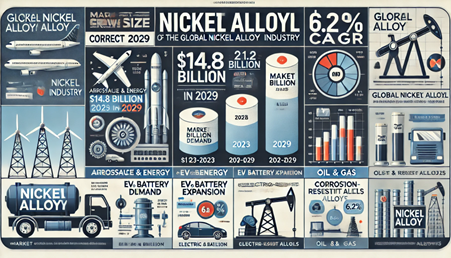

Nickel Alloy Market Analysis: Global Trends, Growth Forecasts, and Industry Opportunities (2023-2029)

Introduction to the Global Nickel Alloy Market

The nickel alloy market is experiencing rapid growth due to its high corrosion resistance, superior strength, and heat tolerance across multiple industries. Nickel-based alloys are widely used in aerospace, energy, automotive, marine, chemical, and electronics industries.

Market Size & Growth Rate (2023-2029)

The global nickel alloy market was valued at $14.8 billion in 2023 and is projected to reach $21.2 billion by 2029, growing at a CAGR of 6.2%. This growth is driven by:

✅ Increased demand for high-performance materials in aerospace & energy industries

✅ Expansion of electric vehicle (EV) battery production

✅ Growth in oil & gas exploration and refinery applications

✅ Advancements in corrosion-resistant alloys for marine & chemical industries

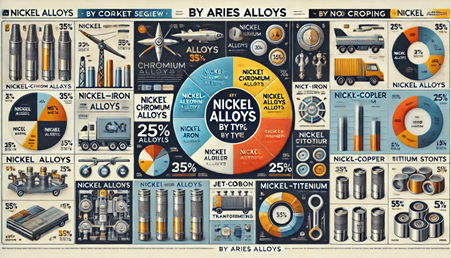

Market Segmentation: Types of Nickel Alloys

1. Nickel-Chromium Alloys (35% Market Share) – Corrosion & Heat-Resistant

🔹 Used in: Aerospace engines, gas turbines, industrial furnaces, and chemical reactors.

🔹 Examples: Inconel, Hastelloy

🔹 Key Features: High-temperature stability, oxidation resistance

2. Nickel-Iron Alloys (25% Market Share) – Magnetic & Electronic Applications

🔹 Used in: Power electronics, transformers, and shielding materials.

🔹 Examples: Invar, Permalloy

🔹 Key Features: Controlled thermal expansion, high permeability

3. Nickel-Cobalt Alloys (20% Market Share) – Superalloys for High-Stress Applications

🔹 Used in: Jet engines, gas turbines, and nuclear reactors.

🔹 Examples: Haynes alloys, Waspaloy

🔹 Key Features: High strength, creep resistance

4. Nickel-Copper Alloys (15% Market Share) – Marine & Chemical Applications

🔹 Used in: Shipbuilding, desalination plants, and offshore oil rigs.

🔹 Examples: Monel alloys

🔹 Key Features: Saltwater corrosion resistance

5. Nickel-Titanium Alloys (5% Market Share) – Shape-Memory & Flexibility

🔹 Used in: Medical stents, automotive actuators, and robotics.

🔹 Examples: Nitinol

🔹 Key Features: Shape-memory effect, biocompatibility

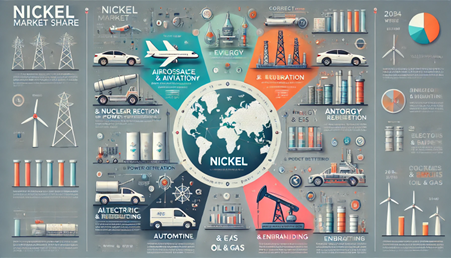

Key Industry Applications of Nickel Alloys

1. Aerospace & Aviation Industry (40% Market Share) ✈️

- Jet Engine Turbines & Exhaust Systems – Heat-resistant nickel superalloys improve efficiency.

- Rocket Components & Spacecraft Structures – Used in NASA, SpaceX, and Boeing projects.

- Aircraft Structural Parts & Fasteners – Lightweight yet strong alloys enhance fuel efficiency.

🌍 Top Regions: USA, EU, China, Russia

2. Energy & Power Generation (20% Market Share) ⚡

- Nuclear Reactors & Steam Turbines – Nickel alloys resist radiation and high temperatures.

- Gas & Wind Turbine Blades – Essential in renewable and fossil fuel power plants.

- LNG & Hydrogen Storage Tanks – Cryogenic-resistant nickel alloys store fuel efficiently.

🌍 Top Regions: USA, Canada, Middle East, Russia

3. Automotive & Electric Vehicles (EVs) (15% Market Share) 🚗

- Nickel-Based EV Batteries – Used in Lithium-Nickel-Cobalt-Manganese (NCM) batteries for longer life cycles.

- Turbochargers & Exhaust Valves – Enhances performance in high-performance cars.

- Structural & Safety Components – Lightweight alloys reduce vehicle weight and improve fuel economy.

🌍 Top Regions: China, Germany, Japan, USA

4. Oil & Gas Industry (10% Market Share) 🛢️

- Corrosion-Resistant Pipes & Drilling Equipment – Extends lifespan in extreme environments.

- Refineries & Petrochemical Processing – Used in heat exchangers and catalytic converters.

🌍 Top Regions: Middle East, USA, Russia, Brazil

5. Marine & Shipbuilding Industry (7% Market Share) 🚢

- Naval Submarines & Ship Hulls – Nickel alloys provide excellent seawater corrosion resistance.

- Oil Tankers & Offshore Rigs – Used in deep-sea drilling platforms.

- Desalination Plants – Nickel alloys improve efficiency in converting seawater to freshwater.

🌍 Top Regions: South Korea, Japan, Norway, USA

6. Electronics & High-Tech Industry (5% Market Share) 📱

- Semiconductors & Circuit Boards – Nickel improves conductivity and heat dissipation.

- Smartphones & Laptops – Nickel alloys enhance battery performance.

- Electromagnetic Shielding – Prevents interference in sensitive electronic devices.

🌍 Top Regions: Taiwan, South Korea, USA, China

Market Challenges & Risks

🚧 Raw Material Supply Chain Disruptions – Dependence on nickel mining in Indonesia, Russia, and Canada.

🚧 High Production Costs – Advanced nickel alloys require expensive refining & processing.

🚧 Nickel Price Volatility – Fluctuating commodity prices affect profitability.

🚧 Environmental Regulations – Stricter policies on nickel mining impact production.

Future Trends & Innovations (2024-2029)

🔹 Nickel-Based 3D Printing (Additive Manufacturing) – Custom aerospace & automotive components.

🔹 Graphene-Coated Nickel Superalloys – Enhancing strength & reducing corrosion.

🔹 AI-Driven Alloy Development – Optimizing material properties for industry-specific needs.

🔹 Nickel-Hydrogen Batteries – Emerging alternative to lithium-ion in electric vehicles.

🔹 Self-Healing Nickel Alloys – Advanced materials that recover from microdamage.