- No.3, 327 S.V.P.Road, Makharai House, Mumbai- 400004, INDIA

- sales@ariesalloys.com

Aerospace Alloys: Advancing Aerospace & Technology

- Home

- Aerospace Alloy Market Analysis

Aerospace-Grade Alloy Market Analysis Report (2025)

Introduction to Aerospace Alloys

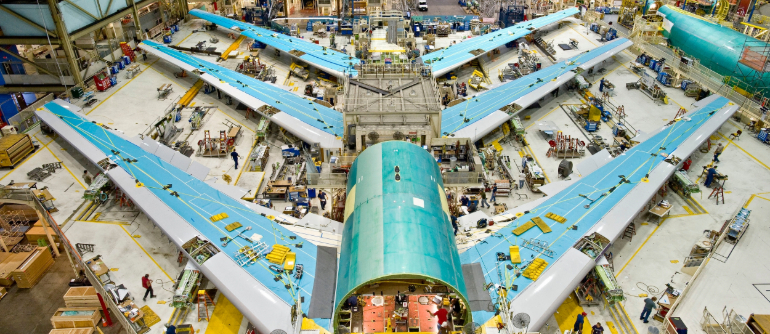

The aerospace industry is a key driver of demand for high-performance metal alloys, including titanium, nickel, aluminum, and specialized steel alloys. With increasing advancements in aerospace engineering and the rising demand for lightweight, durable, and heat-resistant materials, the aerospace alloy market is experiencing significant growth.

Market Overview of Aerospace Alloys

The aerospace alloy market is primarily dominated by Titanium and Nickel alloys, known for their high strength-to-weight ratios, corrosion resistance, and high-temperature performance. The global aerospace industry, including commercial and military aviation, heavily relies on these alloys to enhance efficiency and safety.

Key Market Segments

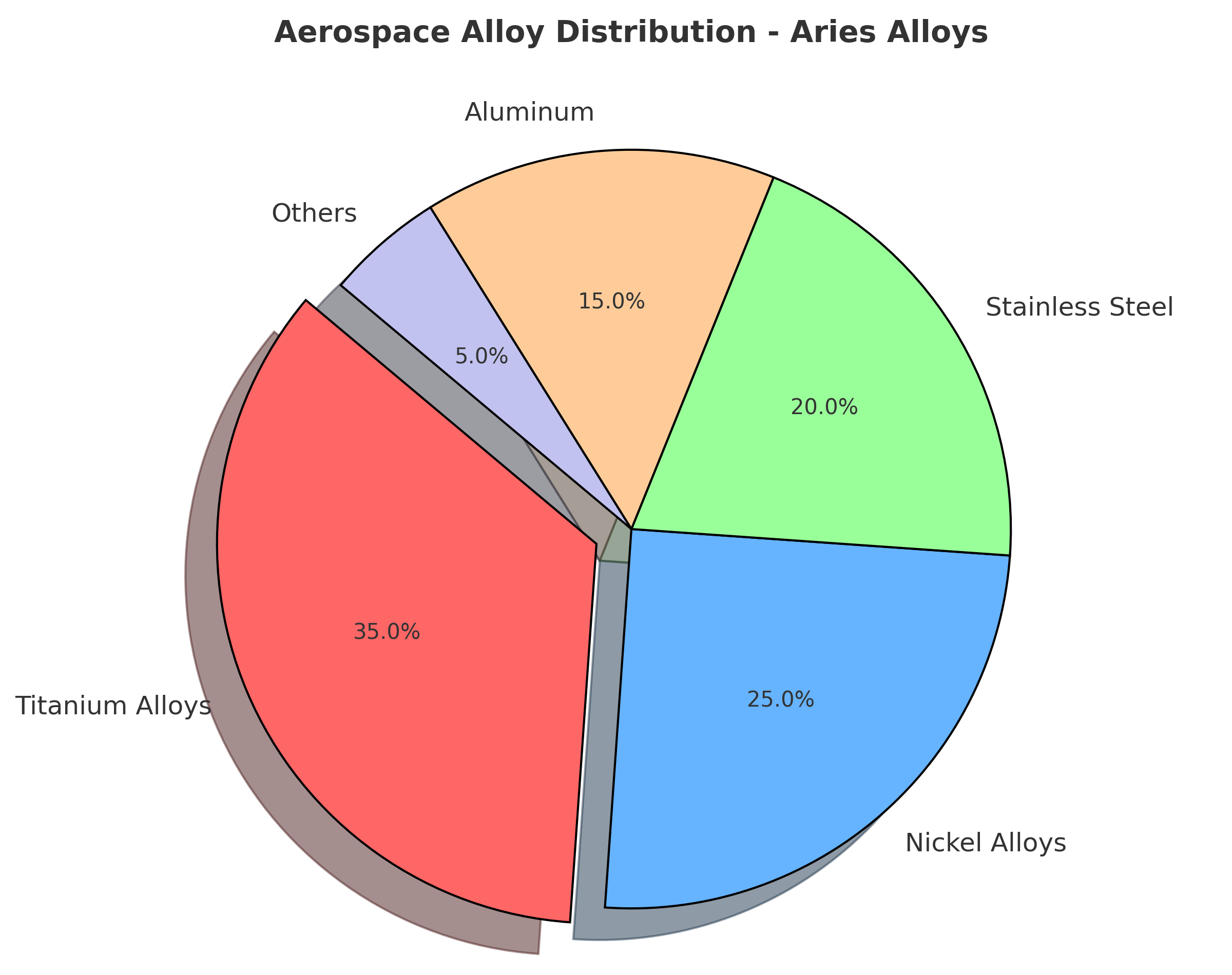

- Titanium Alloys (40%) - Widely used in aircraft structures, engine components, and landing gear due to their exceptional strength, low weight, and high resistance to extreme temperatures.

- Nickel Alloys (30%) - Essential for turbine blades, combustion chambers, and heat-resistant parts in jet engines due to superior oxidation and corrosion resistance.

- Aluminum Alloys (15%) - Preferred for fuselage and wing components in commercial aircraft due to lightweight properties and affordability.

- Steel Alloys (10%) - Used in structural components requiring additional toughness and durability.

- Other Alloys (5%) - Comprise magnesium alloys and composite materials developed for niche aerospace applications.

Market Trends and Drivers

- Increased Aircraft Production: Growing air travel demand is pushing manufacturers to develop fuel-efficient and lightweight aircraft, favoring titanium and nickel alloys.

- Rise in Space Exploration: The emergence of commercial space travel is further driving the demand for heat-resistant and durable alloys.

- Advancements in Manufacturing Technologies: Additive manufacturing (3D printing) has enabled the production of complex aerospace components using high-performance alloys, reducing material waste and production costs.

- Sustainability Initiatives: Recycling and development of new alloy compositions with reduced environmental impact are gaining traction in the industry.

Regional Market Analysis

- North America: Largest market due to the presence of aerospace giants like Boeing, Lockheed Martin, and SpaceX.

- Europe: Strong demand from Airbus and military aviation programs.

- Asia-Pacific: Rapidly expanding aerospace sector in China and India, with increasing investments in domestic aircraft manufacturing.

- Middle East & Africa: Growing airline industry and defense sector investments drive demand for aerospace alloys.

Challenges and Opportunities

- High Material Costs: Titanium and nickel alloys are expensive, impacting adoption in cost-sensitive segments.

- Supply Chain Constraints: Dependence on raw material mining and geopolitical issues may affect supply stability.

- Technological Innovations: Development of next-gen alloys with improved performance and cost efficiency presents significant growth opportunities.