- No.3, 327 S.V.P.Road, Makharai House, Mumbai- 400004, INDIA

- sales@ariesalloys.com

Medical Alloys: Advancing Healthcare & Technology

- Home

- Medical Alloy Market Analysis

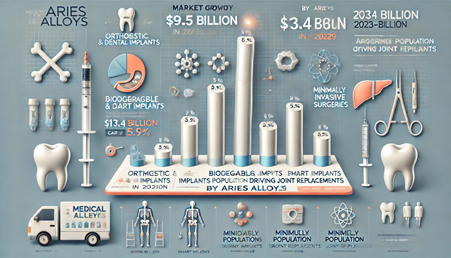

Medical Alloy Market Analysis: Trends, Insights, and Future Growth (2023-2029)

Introduction to Medical Alloys

Medical alloys are high-performance metal materials used in implants, surgical instruments, and medical devices. Their biocompatibility, corrosion resistance, and strength make them essential for orthopedic, dental, and cardiovascular applications.

📈 Market Growth & Projections (2023-2029)

The medical alloy market is projected to grow from $9.5 billion in 2023 to $13.4 billion by 2029, with a CAGR of 5.9%.

🔹 Key Growth Drivers:

✔ Rising demand for orthopedic & dental implants

✔ Advancements in biodegradable and smart implants

✔ Increasing minimally invasive surgeries

✔ Aging population driving joint replacements

Types of Medical Alloys & Their Applications

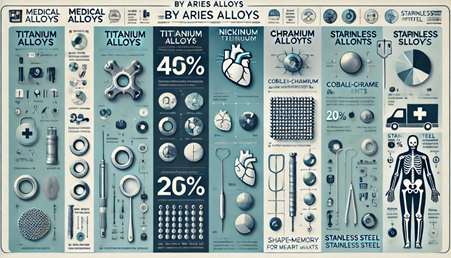

🦴 Titanium Alloys (40% Market Share) – The Gold Standard

Titanium is the most widely used medical alloy due to its:

✔ Lightweight & high strength – Ideal for orthopedic implants

✔ Corrosion resistance – Lasts longer in the body

✔ Osseointegration – Naturally bonds with bones

🔹 Applications:

✅ Hip, knee, and spinal implants

✅ Dental implants and crowns

✅ Bone fixation devices

❤️ Nickel-Titanium (Nitinol) – The Shape-Memory Alloy (25% Market Share)

Nitinol is revolutionizing minimally invasive surgery due to its:

✔ Superelasticity – Returns to its original shape after bending

✔ Corrosion resistance – Withstands harsh body fluids

🔹 Applications:

✅ Stents and guidewires

✅ Catheters and heart valves

✅ Orthodontic wires and braces

🔩 Cobalt-Chromium Alloys (20%) – The Heavy-Duty Option

Cobalt-based alloys are wear-resistant and used in high-load applications.

🔹 Applications:

✅ Joint replacements (hip & knee)

✅ Artificial heart valves

✅ Spinal implants

🏥 Stainless Steel (10%) – The Affordable Choice

While being replaced by titanium & cobalt alloys, stainless steel is still used in:

✅ Temporary orthopedic implants

✅ Surgical tools (scalpels, clamps, scissors)

✅ Dental tools and syringes

Why Medical Alloys Are Essential in Healthcare

✔ Durability – Lasts for decades without degradation

✔ Biocompatibility – Safe for use in the human body

✔ Shape-Memory Effect – Enables flexible implants like Nitinol stents

✔ Minimally Invasive Procedures – Improves patient recovery times

Challenges in the Medical Alloy Industry

🔴 High Costs – Titanium and cobalt alloys are expensive to produce

🟠 Regulatory Barriers – Strict FDA and EU approvals increase time to market

🟡 Material Limitations – Some alloys corrode over time, leading to implant failure

🟢 Supply Chain Issues – Titanium sourcing depends heavily on China

🔵 Need for Innovation – The industry must develop biodegradable & smart implants

Future Trends: Innovations Shaping the Medical Alloy Industry (2024-2029)

🔹 3D-Printed Titanium & Cobalt Implants – Custom implants designed for better patient outcomes

🔹 Biodegradable Magnesium Alloys – Dissolvable implants to eliminate second surgeries

🔹 Smart Medical Alloys – Nitinol implants with drug-releasing capabilities

🔹 Graphene-Titanium Coatings – Enhances implant durability & reduces infections

🔹 AI-Designed Alloys – New metal formulations created for stronger, cost-effective implants

Conclusion: The Future of Medical Alloys in Healthcare

Medical alloys are at the heart of modern healthcare advancements. With innovations in biocompatible materials, smart implants, and 3D printing, the industry is set for massive expansion in the next decade.

🔹 Key Takeaways:

✅ Titanium remains the leading choice for implants

✅ Nitinol is reshaping cardiovascular & orthodontic treatments

✅ Biodegradable implants will reduce repeat surgeries

✅ The medical alloy market will reach $13.4 billion by 2029